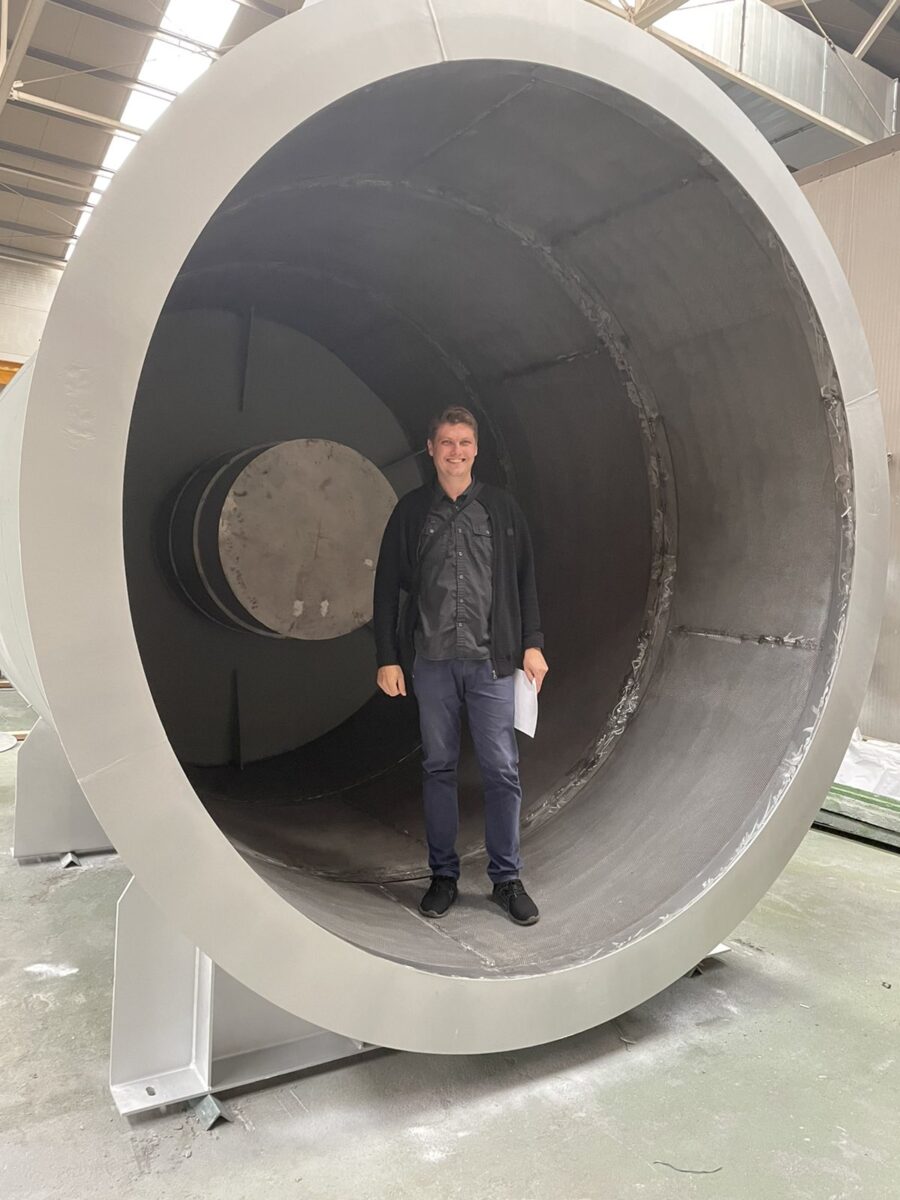

Oversized silencer as the part of valves delivery

For the supply of industrial valves to our important customer in Romania, we also had to use oversized transport. This expeditionary challenge concerned a vertical silencer, which is a part of the valves delivery indented for exhausting a steam turbine into the atmosphere. The total weight of the silencer is almost 4.5 tons.

The system was designed for a steam flow rate of 220t/h, at a maximum inlet pressure of 69 bar and a temperature of 540°C. The DN400 pipe brings the steam to the control valve, where the steam is reduced to a pressure of max. 8 bar. The valve body is a corner construction made of 11CrMo9-10 alloy steel. Inlet valve diameter is DN400 in pressure class PN250 and outlet diameter DN600 in pressure class PN160. Behind the control valve, the steam is then distributed through a DN600 pipe to the silencer. The pressure part of the silencer is designed from 10CrMo9-10 material. The shell of the silencer with a diameter of 3 m and a length of almost 4 meters is then made of low-alloy steel 16Mo3.

The atypical SIPOS electric actuator with which the control valve is equipped is also interesting. This actuator has two motors. The actuator has a force of over 100kN and a stroke of 100 mm. Each motor works independently and has a different function. The task of one of them is precise regulation with a rebuilt time of around 45 seconds. The second motor has the task of quickly opening the valve in about 5 seconds in the event of a malfunction.