Individualized solution of angle valves incl. steam coolers

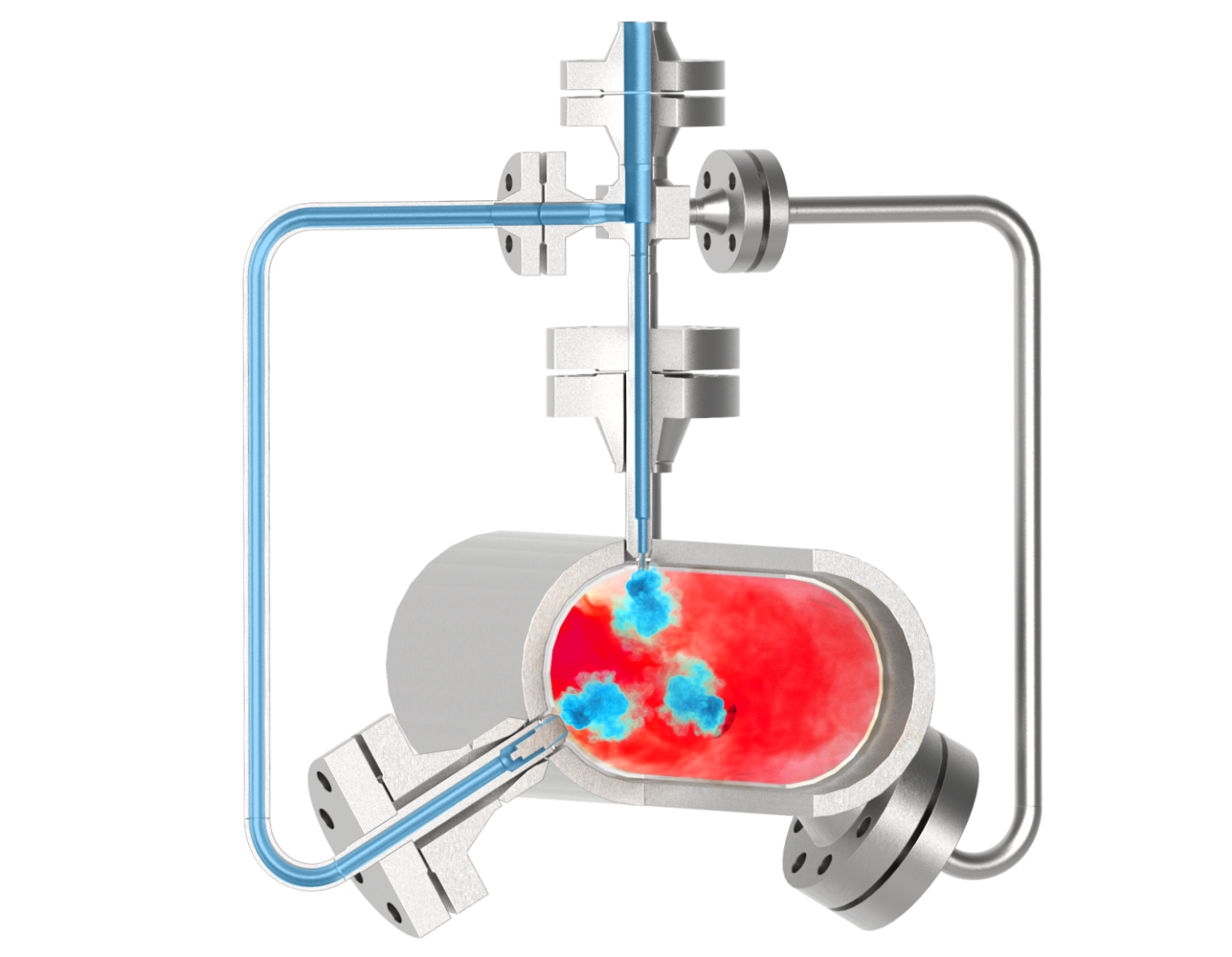

For one of our important clients, which is engaged in the production of boilers for power plants and incinerators, we designed and supplied individualized, high-pressure, angle control valves used to control the amount of injection water in the steam coolers. With regard to the demanding specification conditions (input steam parameters: 150bar, 510°C, flow rate 415t/h; cooling water parameters: 203 bar, 260°C), an individual approach to valve construction was needed, for which a 3-step plug with an enlarged regulation ratio and modified characteristic was designed.

The delivery also included the injection nozzles themselves for high-pressure parameters. A combination of nozzles with variable and fixed geometry was chosen for the design of the coolers in order to cover the client’s demanding conditions for a large range between the minimum and maximum amount of cooled steam (wide control zone).